Steel is the most common tooling material in the wood products industry. This is primarily because of its high strength to cost ratio. Steel is comprised of two basic elements, iron and carbon. The carbon content of steel is crucial in determining its material properties. Steel with high carbon content will be harder, but therefore also more brittle. This means that tools made with high carbon content steel will have a longer tool life and will maintain its edge sharpness better, but will be more fragile. The opposite is also true. If we expect a tool to encounter impurities in the working material, we need it to be tougher. Likewise, a lower carbon content steel would be more appropriate in that situation. (12)

Steels can be mixed with other elements besides carbon to make alloys. These elements are mixed in to improve on the material properties of standard steel such as hardness, heat resistance, edge life, strength, machinability, toughness, brittleness, or corrosion resistance. For example, vanadium can be used to increase hardness and toughness. Normally, these two properties would be inversely related. Another commonly used element in alloys is tungsten. There are hundreds (if not thousands) of alloys that are all specifically engineered for a particular cutting application.

An important steel alloy in wood cutting is referred to as High Speed Steels (HSS). As manufacturing technology advanced throughout the 1900s, production rates increased as well. This caused older steels to fail under the increased friction and heat. HSS was specially formulated to increase the operating temperature of the tool. There are numerous combinations of alloys used in HSS, but they all generally employ chromium, molybdenum, tungsten, and vanadium.

Carbides are also very common in the wood industry. They are harder and have a higher operating temperature than HSS. Subsequently, they last longer and can run at higher speeds. But, HSS is tougher and less expensive than carbide.

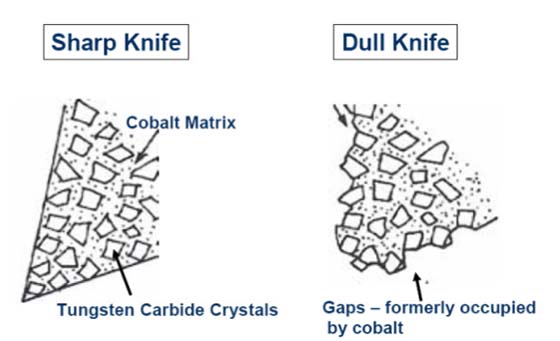

Carbide is comprised of carbide crystals held together in a matrix. The crystals are oftentimes titanium carbide or tungsten carbide. The matrix is generally nickel, chrome, cobalt, or some mixture of the three. Carbide edges usually become dull because the matrix erodes away, not the carbide crystals. (3)

Diamond is the hardest material known to man. In the wood industry they are seen in high-volume machining of particleboard and medium density fiberboard. Diamonds tools have a long lifespan and can be run at very high speeds. But, they are expensive, brittle, and do not allow for a keen cutting edge. It is a common misconception that diamond tools are always better. Actually, it all depends on the application. In many cases carbide tools will perform equally well, but at a fraction of the price. (3)